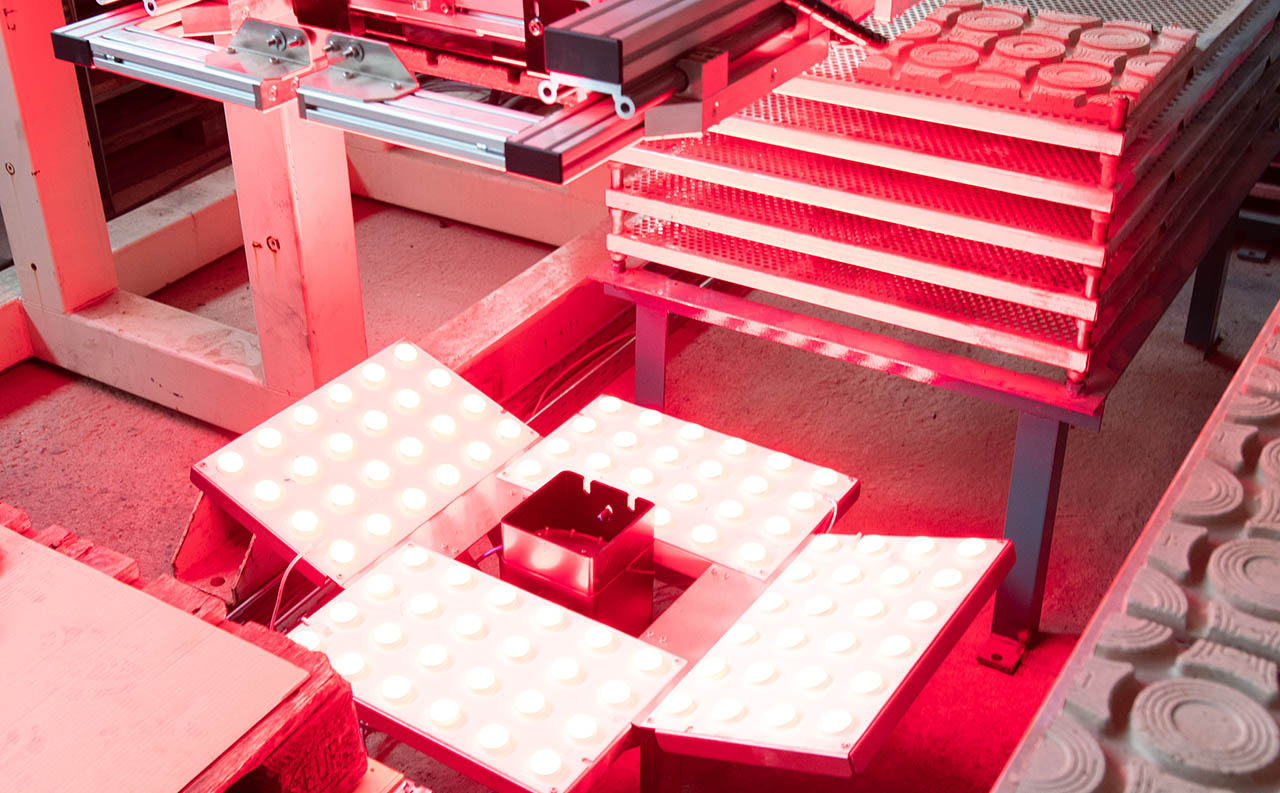

Machine Vision gives your production plant eyes. Cleverly applied, it can determine a wide range of parameters for quality monitoring and process control quickly and reliably.

From shape and position determination, surface finish, color monitoring all the way to dimensional accuracy testing, many properties can be determined and processed simultaneously. There are countless opportunities and advantages, especially in combination with the integration into higher-level IT systems.

On request, we can help you define the requirements for a machine vision system, check the feasibility, select suitable components and define an ideal setup that is not susceptible to foreign light sources or other interference.

Depending on the application, we start with tests before the start of detailed planning, select suitable processing algorithms and evaluate the performance of the concept and the stability of the evaluation algorithms.

As a manufacturer-neutral service provider, we select the best components for you. Thanks to our expertise in software development and image processing, we are able to develop appropriate stable evaluation methods even for very complex problems.